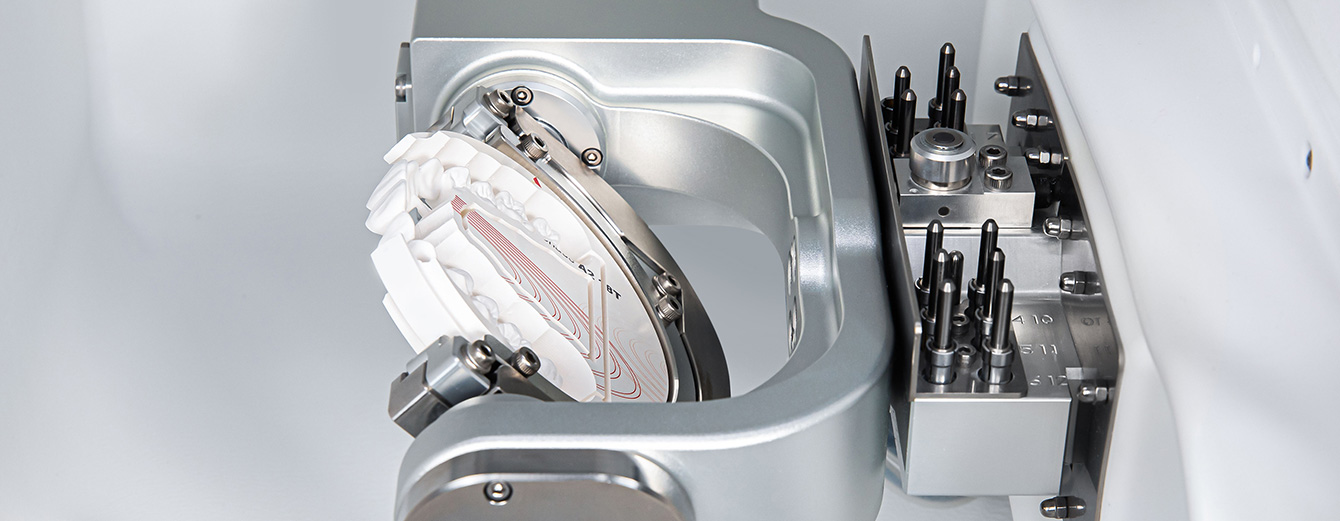

The Arum 5x-300 Pro is a state-of-the-art dental milling unit, meticulously designed to offer unparalleled efficiency, precision, and convenience in dental prosthesis creation. With its unique features, including an efficient C-TYPE JIG and an all-in-one system, this model stands out as a comprehensive solution for modern dental practices. Whether it’s the intricate details of the labial side or the high-speed processing of glass ceramic materials, the Arum 5x-300 Pro ensures top-notch results every time

Arum Dentistry 5X-300 Pro CAD/CAM Milling Machine

Availability : In stock

Brand :

Arum Dentistry

Milling Machine offers precise dry milling for dental prosthetics, with versatility and user-friendly features, ideal for modern dentistry.

₹

23,00,000

₹

24,75,000

7% off

Packaging

- 1 x Arum 5x-300 pro CAD/CAM Milling Machine

Packaging

- Initial Setup: Ensure the milling machine is correctly installed and connected to a compatible computer with the necessary CAD/CAM software installed.

- Material Selection: Choose the appropriate dental material (e.g., Zirconia, PMMA, Wax, PEEK, Nanocomposites) based on the specific dental prosthetic you plan to create.

- Material Loading: Load the selected material into the machine's material holder, ensuring it is securely positioned.

- Software Initialization: Launch the CAD/CAM software on the connected computer and configure it to work with the Arum 5X-450 Milling Machine.

- Design and Toolpath Generation: Within the CAD/CAM software, design the dental prosthetic according to patient specifications. Generate the necessary toolpaths for milling.

- Machine Calibration: Calibrate the milling machine according to the manufacturer's guidelines to ensure precise milling.

- Tool Preparation: Prepare the appropriate milling tools as recommended by Arum for the specific prosthetic design.

- Start Milling: Initiate the milling process through the software controls. The machine will follow the generated toolpaths to shape the prosthetic from the chosen material.

- Real-Time Monitoring: Monitor the milling process on the machine's control panel or through the software. Ensure that the milling operation proceeds smoothly.

- Quality Control: After the milling is complete, inspect the dental prosthetic for accuracy, surface finish, and any imperfections. Make any necessary adjustments or refinements.

- Material Replacement: If needed, replace the milling material (e.g., material blocks) for subsequent milling jobs.

- Clean and Maintain: After use, clean and maintain the milling machine and tools to ensure longevity and hygiene.

- Patient Integration: - Incorporate the milled dental prosthetic into the patient's treatment plan, ensuring proper fit and function.

Features

- With the use of an open C-type cartridge, you can precisely machine the Labial Side (Buccal Side) and Under-Cut zone which requires additional machining.With the amazing power of the best-in-class spindle AC 1.28kw, you can machine various shapes and materials such as Denture, Zirconia, CAD Block, and Titanium milled Bar. etc. (Except for Ni-Cr / Co-Cr Disk).

Machining with the removal of the connector

- You can mount 5 Pre-milled Blanks and a Customized Abutment with the removal of

Connector using AT Holder and Attachment. The removal of the Connector increases the degree of bonding with the upper prosthesis and reduces the workers’ post-stage work, improving work efficiency.

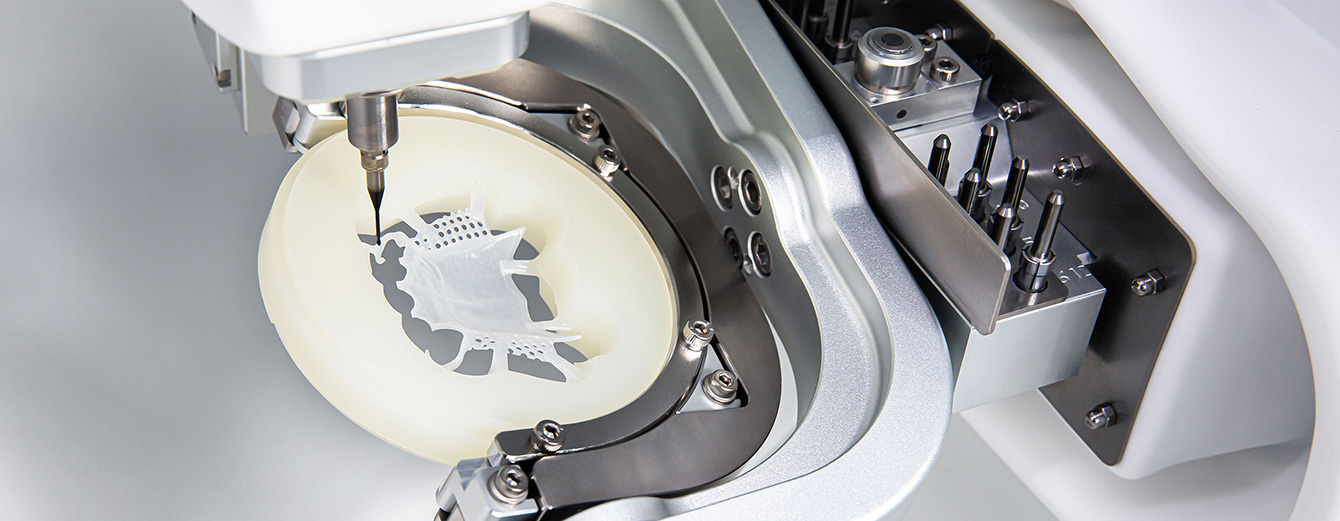

Differentiated round bar machining

- You can machine the Cuff Side (Gingival area), Occlusal Side, Connectorless, and Retention Groove in simple Top and bottom Side milling using an AT cartridge. Anyone can easily produce high-quality Customized Abutments.

Dedicated template for ARUM, Outcome of our extensive know-how

- With the application of our know-how in ‘Machining the dedicated template for ARUM and Implant Connection’ accumulated through our experience of machining 5X-200 screw-type prostheses to 5X-450, you can machine high-quality screw-type prostheses (Bar, Screw Retained Crown & Bridge). This is ARUM's unique asset that cannot be provided anywhere else.

Maintenance of the best-use conditions

- With the Auto Calibration Function, users can maintain the best condition of the machine anytime. In particular, with the Auto Calibration function by the location of Pre-milled Blank,you can produce high accuracy Customized Abutment.

Check Delivery Availability

Similar Products

Orikam P53- 5 Axis Dry Milling Machine

₹ 1,300,000 M.R.P : ₹ 1,600,000

Roland Milling Machine DWX 520 i Plus

₹ 1,300,000 M.R.P : ₹ 2,500,000

UPCERA A51 Dry Milling Machine

₹ 1,350,000 M.R.P : ₹ 1,900,000

Arum Dentistry 5X-300 Pro CAD/CAM Milling Machine

₹ 2,300,000 M.R.P : ₹ 2,475,000

You May Require This Also

OHC DENTAL CHAIR GOLD (FULLY AUTOMATIC)

₹ 115,000 M.R.P : ₹ 125,000

OHC COMPRESSOR OIL FREE - 1HP

₹ 16,000 M.R.P : ₹ 25,000

OHC DC Portable X Ray

₹ 65,000 M.R.P : ₹ 100,000

OHC Wall Mount Dental X - Ray Model 03/25

₹ 29,900 M.R.P : ₹ 50,000

Oralhealthcart Products

Oralhealthcart Products